by Robert Teng

Every project requires site specific recommendations based on its native soils and material used on site. Evidence comes from the exploration of these soils obtained through borings, test pits, probes, hand augers, and samples grabbed off stockpiles. Multiple samples from a variety of areas around the site are typically taken to form the best idea of what subsurface conditions look like. Soil types and their properties can vary tremendously, which is why every site has to be thoroughly explored. The three most common laboratory tests conducted here identify soil saturation, particle size/distribution, and maximum dry density. These tests are called moisture, sieve, and proctor analysis.

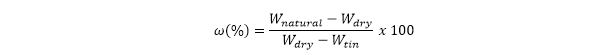

All moisture content determinations must follow ASTM D2216-10 Standard Methods for Laboratory Determination of Water (Moisture) Content of Soil and Rock by Mass (ASTM D2216). To summarize, the first step is to record the weight of a tin to hold the sample, then the combined weight of the sample and tin gets documented. Once recorded, both go into an oven set to a low and uniform heat setting. Typically, the sample will not be dry until the following day. Once the sample is dry its weight is recorded once more. With these three weights the moisture can be calculated by following the equation below.

Moisture content helps determine a soils usefulness at its current saturation. Knowing a soils current moisture content can be a great advantage like during construction backfill and compaction. The farther a soil is from its optimum, the more difficult it becomes to work with and the greater risk for something to go wrong.

All grain size distribution analysis must follow D6913-04(2009) Standard Test Methods for Particle-Size Distribution (Gradation) of Soils Using Sieve Analysis (ASTM D6913). To summarize, a grain size analysis determines the size of particles and the distribution of those sizes across a particular sample. The test begins with first going through a moisture determination, then the dry material can be sieved by hand or using a machine. A sieve is a wired mesh held together by a frame, used to allow smaller soil particles through and retain larger soil particles. A collection of sieves is put together to form a tower, gradually decreasing in void space as you go down. The sample is poured in at the top and its tin placed back on the scale. Each sieve is individually shaken with a bottom catching the smaller soil particles. Once that only the larger soil particles remain, the particles are dumped back into the tin. The bottom, catching all of the passing particles, gets dumped back into the sieve tower. The accumulated weight in the tin is recorded and the process is repeated for every sieve. Once through the tower, a distribution of the soil particles will be formed.

Grain size distribution analysis helps classify a soil in accordance with Uniform Soils classifications. A soil classification allows those knowledgeable to provide recommendations based on that soil type and its properties.

All modified proctor tests must follow ASTM D1557-12e1 Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 ft-lbf/ft3 (2,700 kN-m/m3)). There is also a Standard test method following ASTM D698. To summarize, a proctor produces a maximum dry density and optimum moisture content that is used for checking construction compaction out in the field. The test starts off by weighing the total amount of material, typically a little more than a 5-gallon bucket. The accumulated weight of all particles bigger than a ¾ inch sieve gets documented, along with the weight of all the material smaller. Only the soil that passes through the ¾ inch sieve is used for testing, but the amount of material retained is used to calculate rock corrected values.

[2x repeat] The bottom two components of the proctor mold get weighed before the test. Once the proctor mold is fully assembled and tightened the first lift of soil can be scooped in, followed by 56 blows delivered by a proctor hammer. The soil refill and compaction will be repeated 5 times until the mold is filled slightly above the line between the lower and upper mold sections. After the compaction of all 5 lifts, the top piece of the mold is removed. Excess soil above the lip is scraped off and made as flush as possible. This weight of soil and mold is recorded, then a moisture determination is run on the compacted soil. These tasks are repeated twice more at a slightly dry and slightly wet moisture.

A proctor test consists of three tasks, testing a natural, dry and wet sample. These three tasks will provide data points on a graph, which will help determine the soil’s MMD and optimum moisture. The (MMD) maximum dry density is the compacted density of a soil at optimum moisture. The MMD and optimum moisture serve as a soil specific check for field compaction testing. These values are used in the field to determine if soil is adequately moisture conditioned and compacted.

There are many more testing procedures that could have been mentioned, such as Atterberg Limits, Sand Equivalent, Hydrometer, etc. The Riley Group, Inc. (RGI) has extensive experience in performing these kinds of laboratory tests. We are here to provide the necessary information and service of laboratory work to all of our clients and fellow consultants. If there are any PNW projects needing our assistance or you would like to learn more, feel free to contact us at info@riley-group.com.